|

<< Click to Display Table of Contents >> Ruled Surface blade |

|

|

<< Click to Display Table of Contents >> Ruled Surface blade |

|

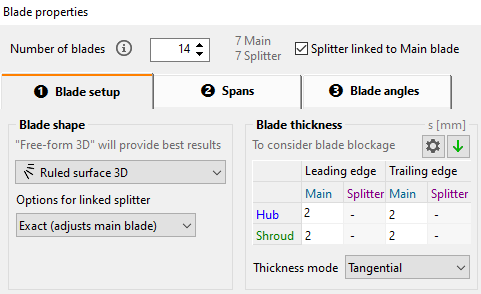

Ruled surface blades are used especially to enable flank milling for manufacturing. The mean surface is generated by spatial movement of a straight line.

When using splitter blades that are linked to main blade then this linkage can be specified in more detail.

You can choose between the following options:

Exact (adjusts main blade): The blade geometry of the splitter is forced to be equal to its main blade. Therefore, the leading edge of the splitter needs to be a ruling of the main blade. Due to the flexible choice of the splitter leading edge, this option requires a readjustment of the main blade.

Mean lines only: The blade geometry of the splitter is designed using the mean lines of the main blade. The advantage of this option is a higher flexibility in design of a curved leading edge of the splitter. (depends on the number of mean lines)

The following pictures illustrate the combination of different options (splitter is rotated into the main blade for illustration):

|

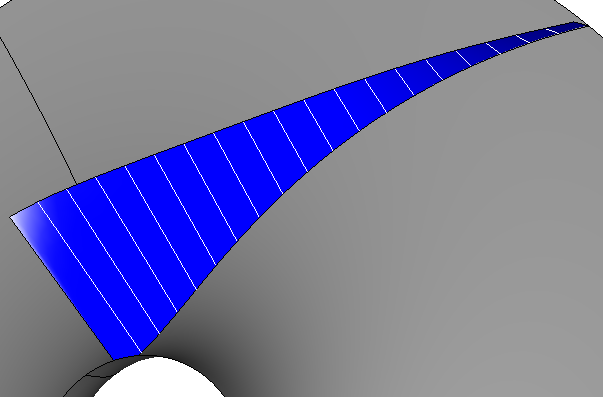

•Splitter linked to Main Blade •2 spans •Exact (adjusts main blade) Main and Splitter are using identic rulings. The splitter leading edge is influencing the rulings and therefore the main blade. |

|

•Splitter linked to Main Blade •2 spans •Mean lines only Main and splitter are using their own rulings. The splitter is guided by the hub and shroud mean lines of the main blade only. The resulting splitter shape can slightly deviate from the main blade. |

|

•Splitter linked to Main Blade •5 spans •Mean lines only The splitter is guided by all 5 mean lines of the main blade. The resulting splitter shape is following the main blade and can have a curve leading edge but it's no more a ruled surface. |

|

•NOT Splitter linked to Main Blade •5 spans Main and splitter are using their own rulings. There is no coupling between splitter and main blade. The splitter shape can highly deviate from the main blade. |