|

<< Click to Display Table of Contents >> Automatic calculations |

|

|

<< Click to Display Table of Contents >> Automatic calculations |

|

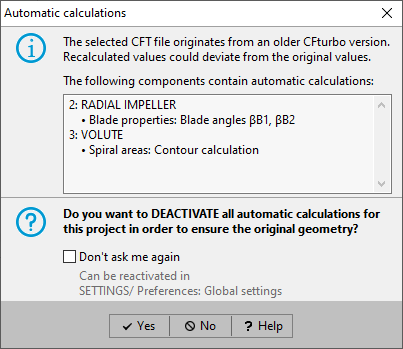

Some component design steps contain automatic calculations. ![]()

Currently these are:

•Impeller main dimensions: calculation of empirical parameters and efficiencies, calculation of dimension values

•Impeller blade properties: calculation of blade angles βB1, βB1 (meanline design mode) or Profile properties (airfoil/ hydrofoil design mode)

•Volute development areas: calculation of spiral contour using updated inlet flow properties

These automatic calculations can be activated or deactivated. Both approaches have their specific advantages and disadvantages:

•Automatic calculation:

It's assured that the calculation results are up-to-date based on the latest input parameters.

The formerly used values could be be modified.

•No automatic calculation:

It's assured that the exact original values are used, which were calculated or specified formerly, including optional manual adjustment.

The values could be not suitable to any modifications of input parameters or modified geometry parts.

When opening older CFturbo projects containing automatic calculations the calculated values can deviate from the original values due to the re-calculation - therefore the geometry could be modified slightly compared to the original one. Generally it's recommended to deactivate all automatic calculations after the design process is finished and the CFturbo file is archived.

If a CFturbo project was created by an older version and contains automatic calculations the user will be asked for deactivating it when opening such a file. This should assure identical geometry over several CFturbo versions.